Ever since the Industrial Revolution, people have looked for ways to make production and distribution faster and more efficient. Automation has become a hot topic recently due to changes in the workforce and most of all, the drastic change in the way customers are shopping. Now more than ever, the lowering of costs and the increasing of productivity has become paramount.

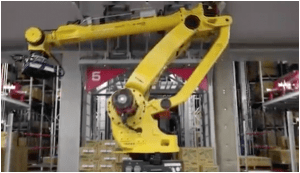

A fully automated warehouse means a site that runs without people. Once storage is installed, the complete process of selecting stock, replenishment, and shipping is actioned via automation. Find out more about Shelving Ireland at Rackzone. It might sound odd to have a site that runs without the need for people, so what are the advantages of adopting such a system?

Labour – Full automation reduces the high costs associated with labor. This type of system is beneficial in areas that see very high land and workforce costs.

Land – With land being at a premium, an automated site could take advantage of height instead of taking up valuable acreage. An additional benefit to this is that it maximizes space as goods can be stored at a higher density as well.

Energy Reduction – The costs of energy can be reduced as, without people, operations can take place at reduced lighting levels, for example.

Continuous – With automation run on software, a site can be operational 24 hours a day and 365 days a year without interruption.

Reducing workplace accidents – If there is no workforce on site, there is less chance for injury to people. Workplace injury, accidents, and even death is a big problem for many industries, especially those in construction or those working in close proximity to heavy machinery.

What should I consider when deciding if automation is right for my business?

One of the biggest questions to ask if it will achieve a return on the original investment. The initial outlay will be sizeable indeed and this can be off-putting. However, there will be significant cost savings in terms of land use, energy costs, and staff wages. For those with an existing warehouse will need to think about the impact of automation on current staff and suppliers.

How can I switch an existing site to automation?

This will require a lot of thought and planning and not all operational sites will be suitable for conversion to full automation. Another important element to consider is how much downtime your business will experience during the changeover. Could the business afford to lose revenue as the change takes place?

For those looking for a compromise, part-automation is a popular solution.

What are the advantages of adopting a part-automation approach?

A site can be retrofitted, and it is a cheaper option for full automation in many cases. Businesses can keep their staff whilst also maximizing available space. It is also a step in the right direction to full automation, making the possible switch easier in the future.